Plant Management

Our Daily Op-Smart meeting is the most important activity of the day.

It refocuses us daily on what we’ve accomplished and what keeps us from accomplishing more. Our weekly and monthly performance meetings are about what we’ve done to improve not why we struggled to meet watered down expectations. We know if we don’t improve constantly – we put ourselves in jeopardy.

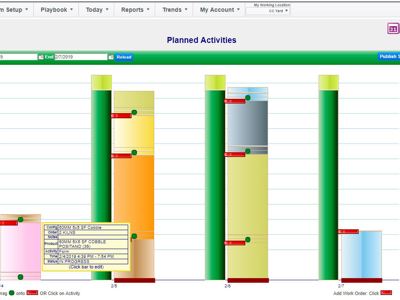

Today's Results

- Raw Materials to Finished Goods

- Review Production activities REAL TIME, as production events are captured automatically, and continuously!

- Leverage production opportunities you might not have been aware of until hours – or days – later, in a paper-based process..

- Ensure daily production and downtime information is accurate while activities details are still fresh!

- Watch your month-end report scramble disappear, as OpSmart aggregates your accurate daily production information continuously, for viewing in weekly and monthly reports.

Productive Meetings

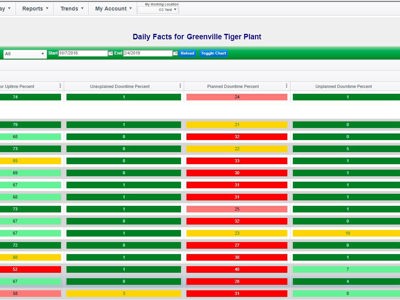

Accurate and timely information are essential for productive meeting! Expedite daily meetings, using Op-Smart to:

- Confirm (not reconstruct) daily Production Numbers and downtime events

- Drive “Unexplained Downtime” to 0%

- Analyze (not reconstruct) Barriers to Higher UpTime

- Prioritize and Resolve what will be done differently going forward

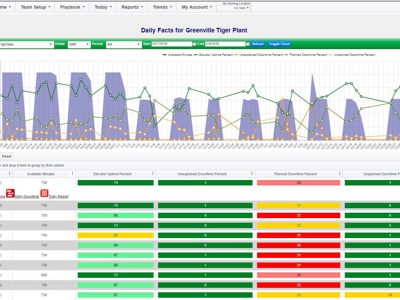

Steady Improvement

Steady Improvement depends on accurate, timely information that is used and analyzed…If you can’t measure it…you can’t manage it…you can’t improve it.

Op-Smart provides Business Date Facts, used for trending analysis, which makes anomalies easy to spot:

- Includes key metric displays RAG (red-amber-green) alerts, against a plant-established (lean informed) target

- is updated daily, and can be reprocessed as needed if underlying data is modified

- is available at daily, weekly, monthly level

- is available in multiple views (reports) of the data, including principles of Lean Manufacturing

- Displays in linear or graphic

- Can be Exported (Excel, pdf)