Opportunity

You are not alone in this journey! Op-Smart is your lean manufacturing partner, working closely with you at scheduled intervals to share insights about your Op-Smart data, from 40 years experience in multiple industries.

- Opportunities become visible and actionable, starting on day #1

- Opportunities are most effectively processed as a team at the daily plant meeting, sharing the same production and downtime information, then talking about what it means and how to improve

- Opportunities continuously surface the obstacles to Up Time improvements, always focusing on the next “top three” opportunities – indefinitely!

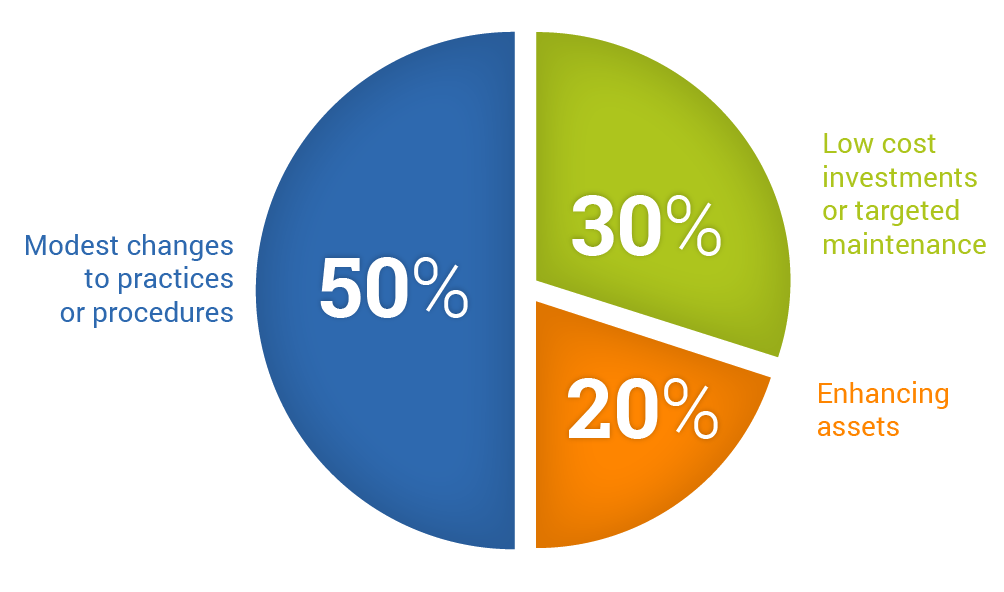

Expected Improvement Areas

50 % – Practices

Easy to identify and remediate

Usually found in the first 1-6 months of project, but continue to be found indefinitely

- Consolidate mold clean with shift change

- Eliminating start up, cleanup and break abuse

30% - Low Cost Improvement

Require more data / certainty

Many are found in the first 1-6 months of project, but continue to be found indefinitely

- Minor Equipment repair, upgrades

- Priority-Impact Maintenance

20 %– Asset

Usually confirmed in months 6-12 months of project, in conjunction with annual capital appropriations

Op-Smart plant managers typically get more capital appropriations than those that do not use Op-Smart to support their requests

- Replace wrapper

- Roboticize key operations